When designing a new machine, the main concern is to build it and bring it to market as quickly as possible. Any delay, complication or failed prototype can damage the overall project results.

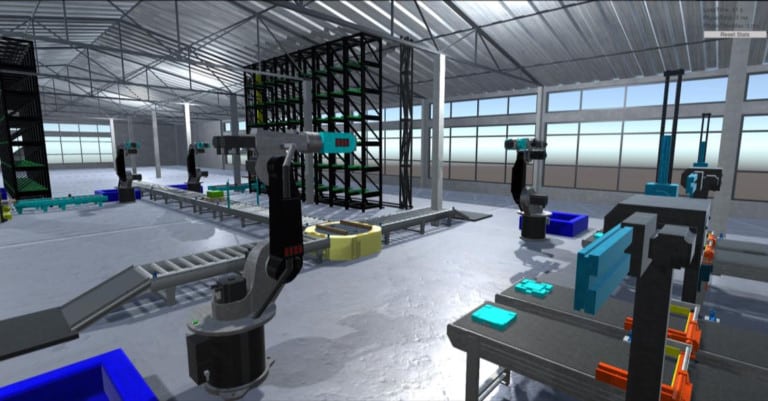

To overcome these problems, the Digital Twin concept was born. A Digital Twin can follow a machine or industrial plant throughout its life cycle, from conceptual planning to after-sales services. It can be developed in parallel with mechanical design and adapted, improved and tested. It offers the ability to simulate machine hardware and software in real time production processes.

The virtual use of the machine allows technicians to design modifications and improvements, test them and return them to the original design, in development and test cycles within an overall plan. These cycles, performed before the realization of the machine or plant, are much faster and less expensive.